Home

Liquidtool

Role

UI/UX & Product Design

6 months

Tools

Background

CNC machines require coolant for them to run for long hours in a production setting. The health of the coolant directly correlates to the performance of the machine and therefore the coolant requires constant monitoring. Traditionally, this involves a specialist having to manually monitor the coolant and record measurements to maintain its health.

Business IoT App

Mobile App

The Goal

The Design

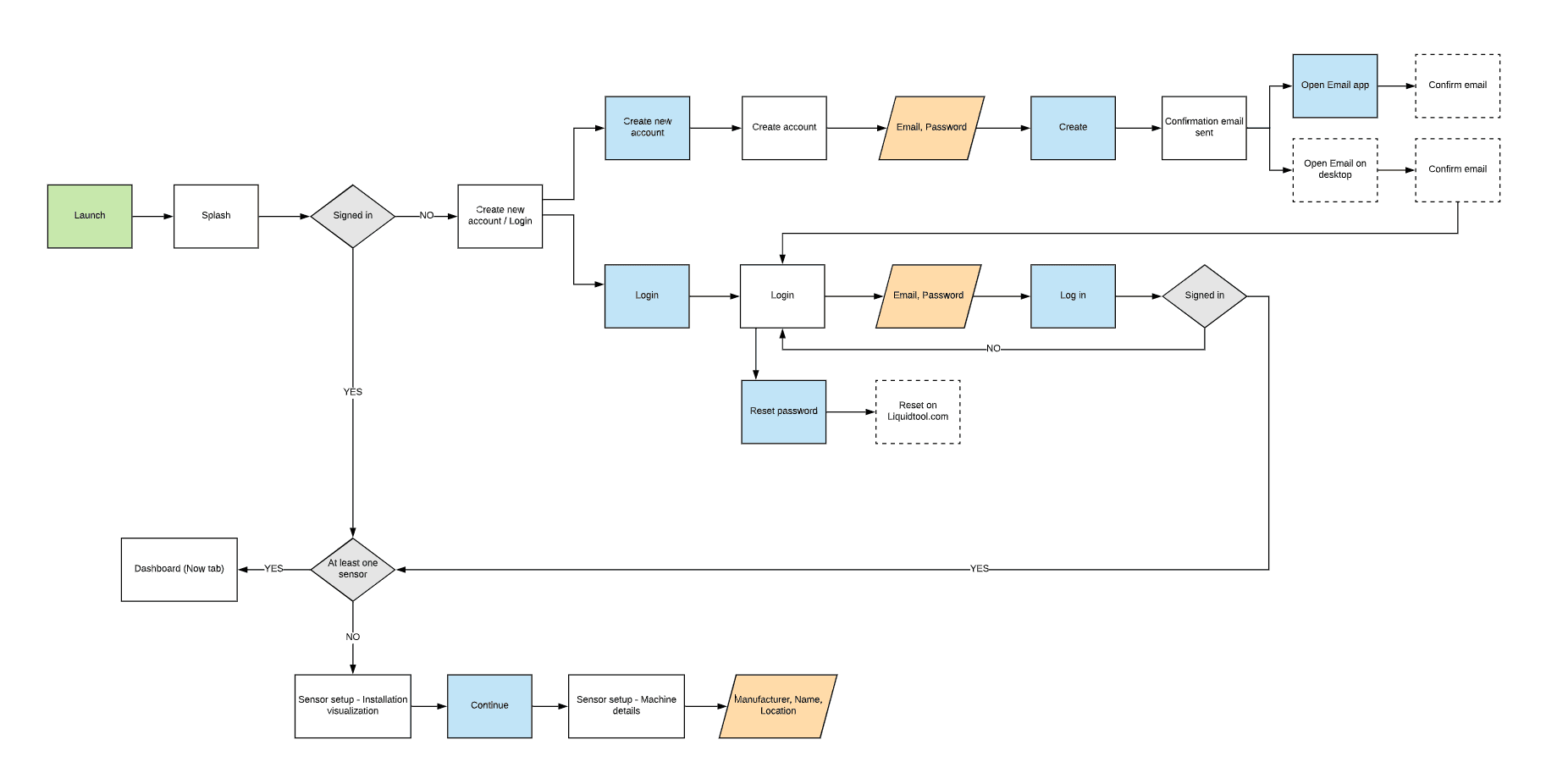

Connecting to the Sensor

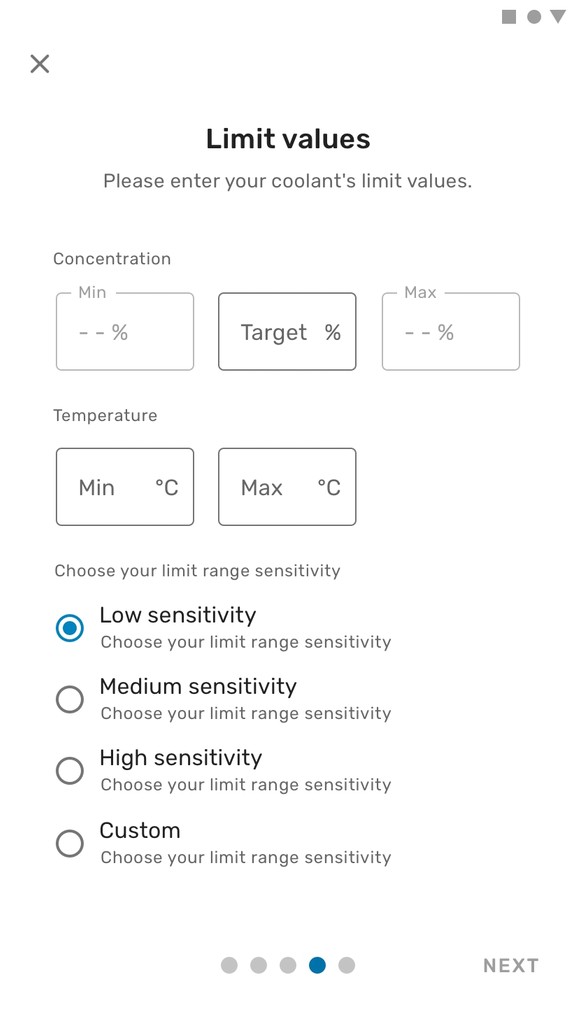

We wanted to make the sensor setup as easy as possible for the specialists as this would be entirely novel to them. It should be said that they generally aren't the most tech savy bunch as well, therefore a simple wizard instructing them on how to set it up would be the way to go.

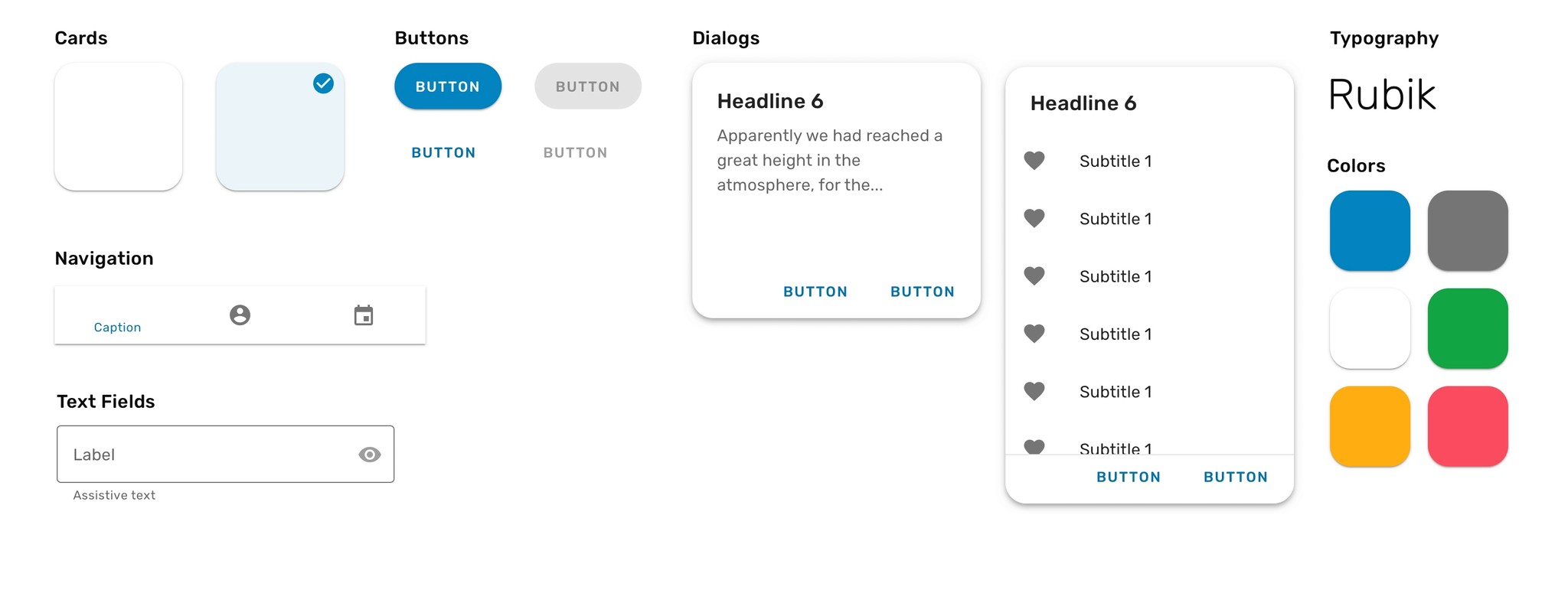

Setting the Theme

Before designing the app, I started by creating a simple theme and some components that would lay the foundation of the app's design. I based it largely off of Google's Material Design system because I felt like using a minimalistic, natural-looking design would work well with an app that is intimately connected to the physical world.

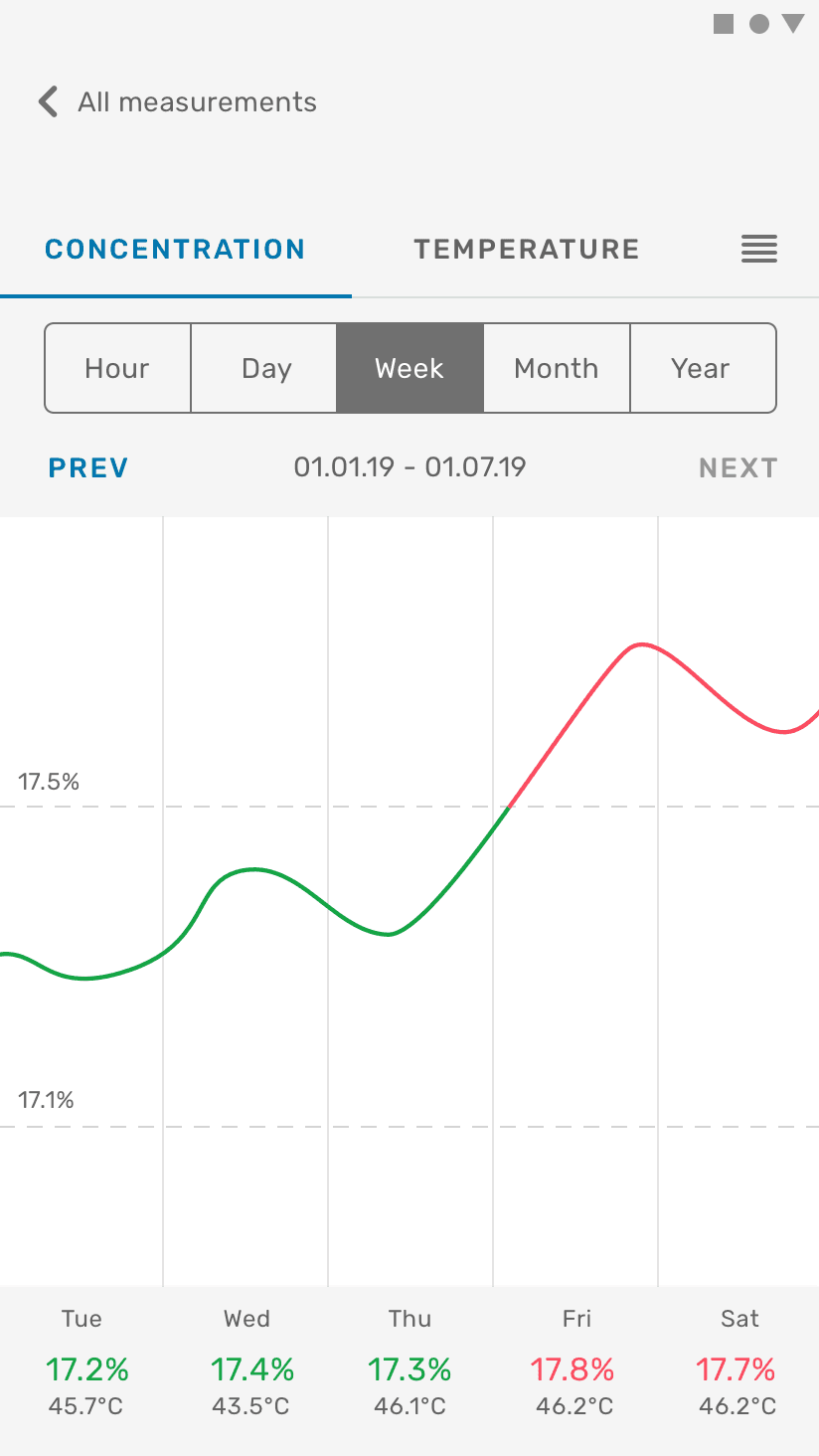

Monitoring the Coolant

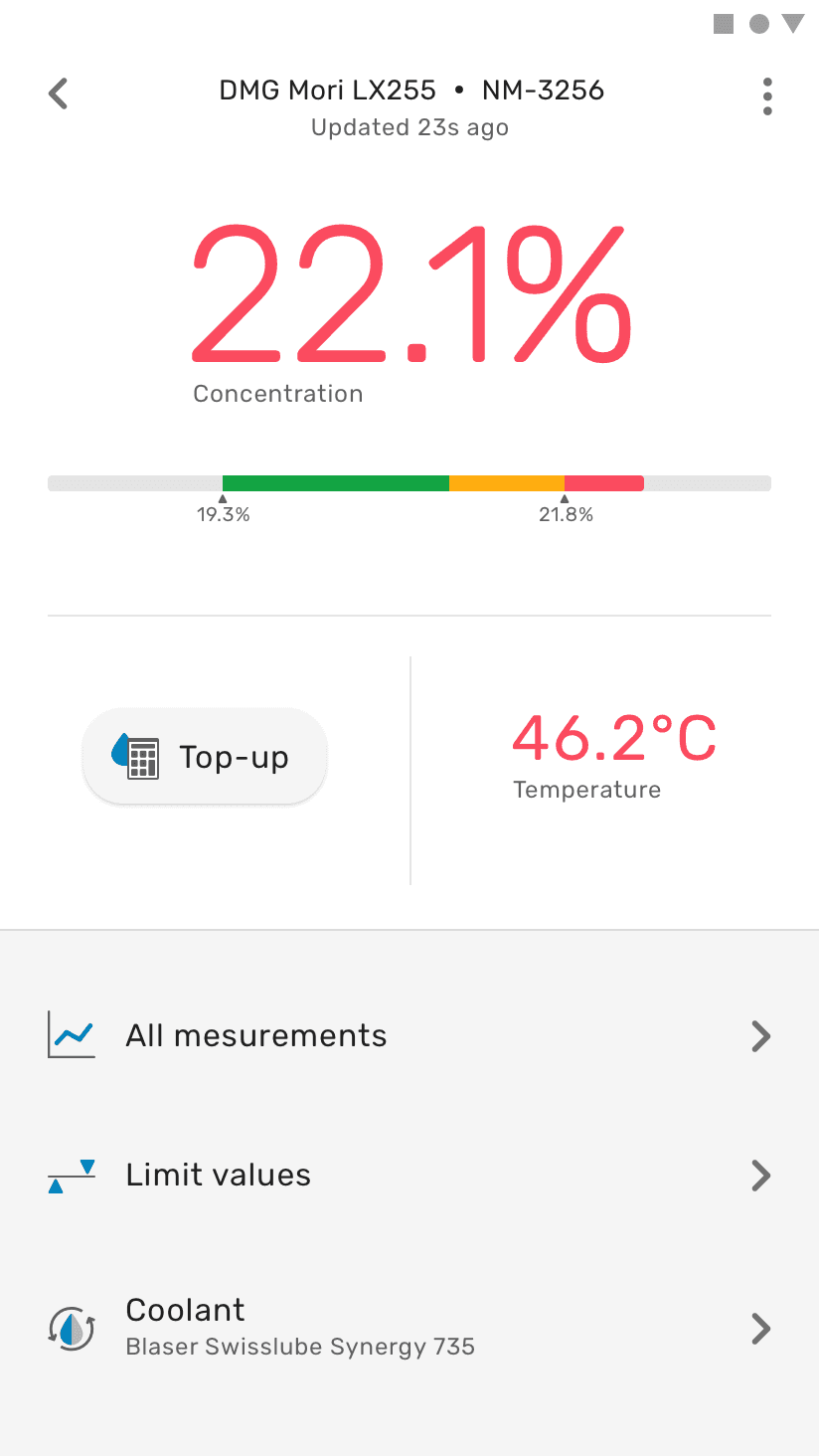

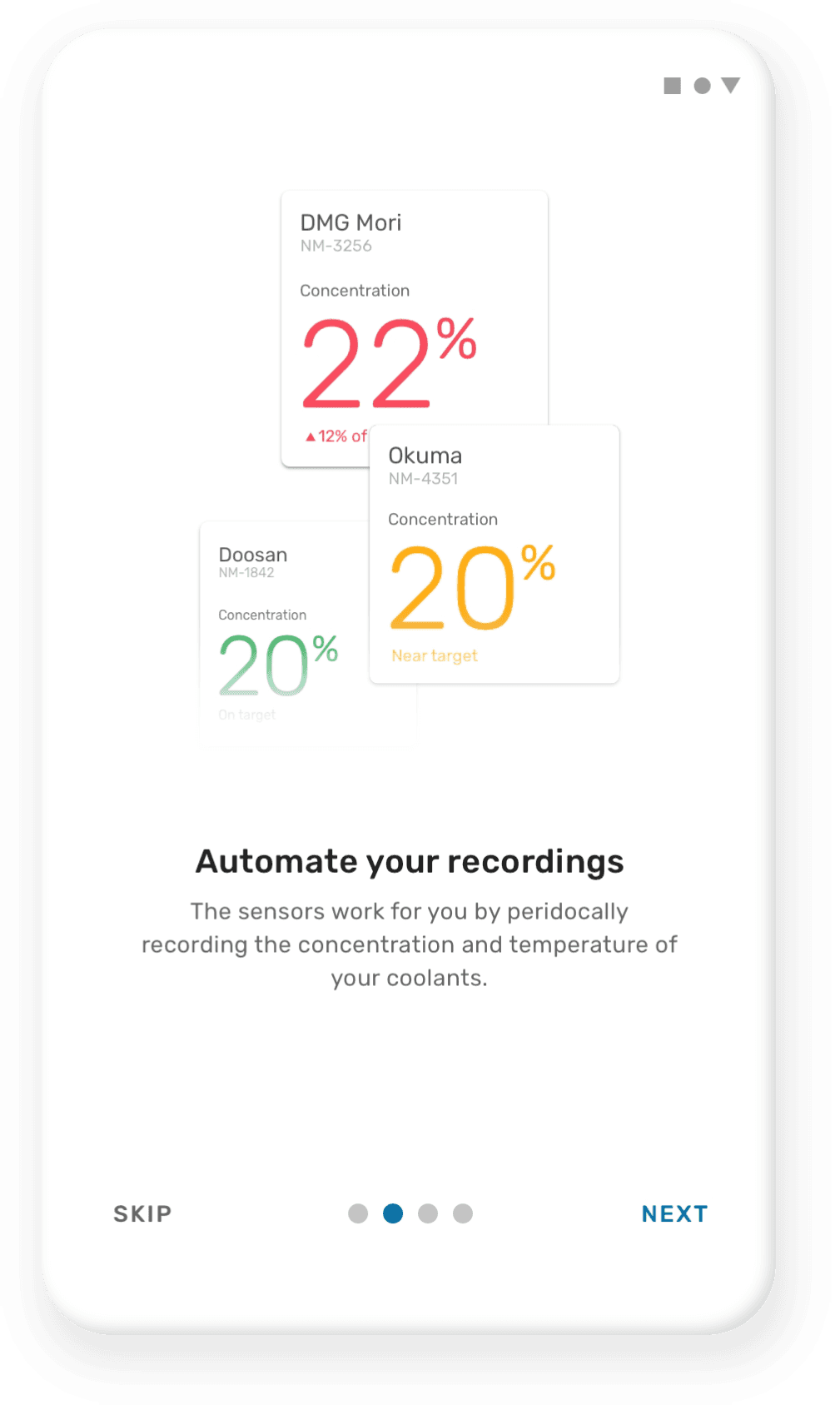

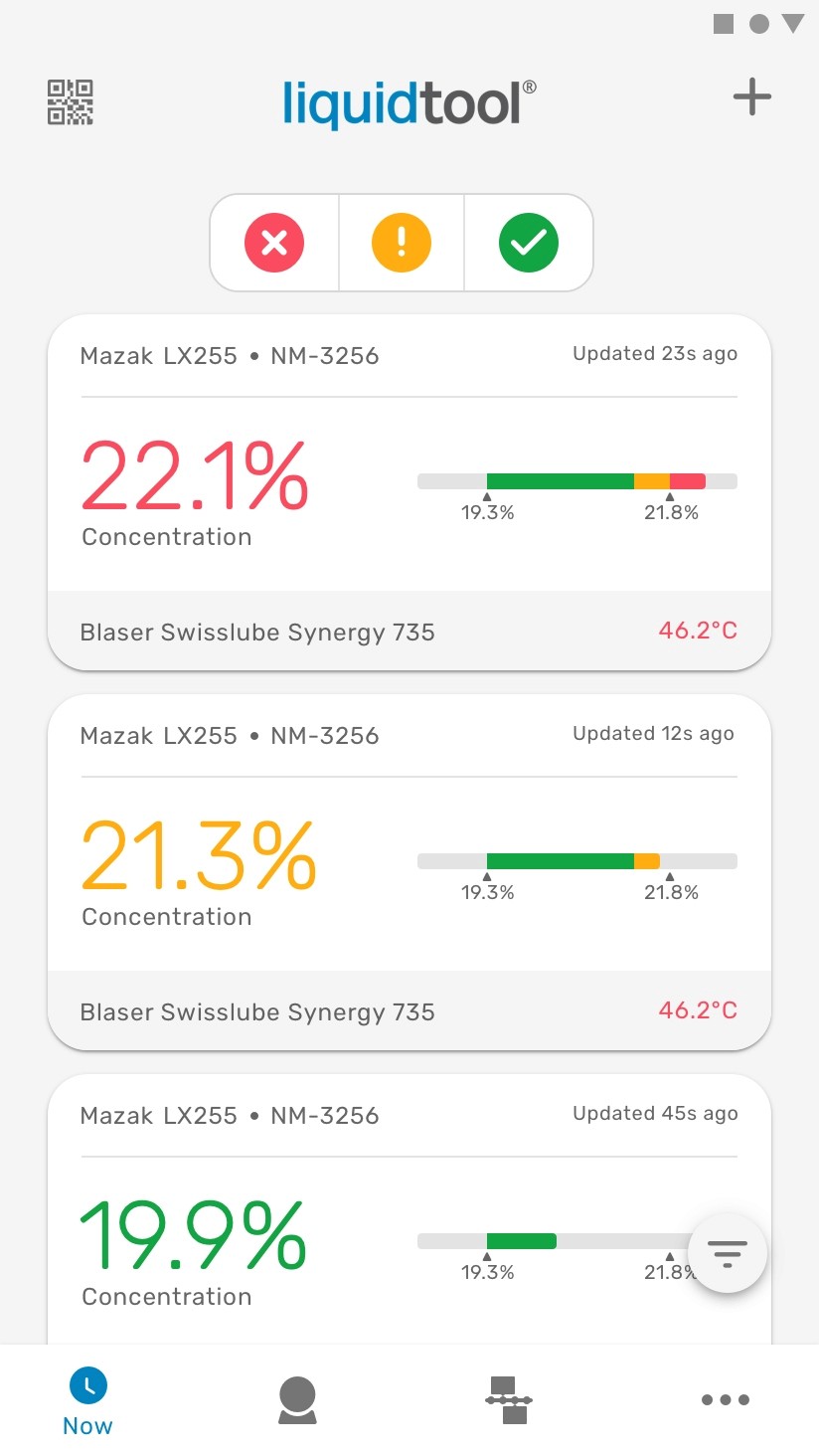

Real-time Measurements

One critical function of the app is to receive real-time measurements directly from the sensor. We needed a way to visualize this in a way where operators could glance at all their operating machines and quickly determine how healthy the coolant is. We came up with a design that focused on displaying the concentration and a dynamic infographic so that they can see exactly where the recording is with respect to its limit values.

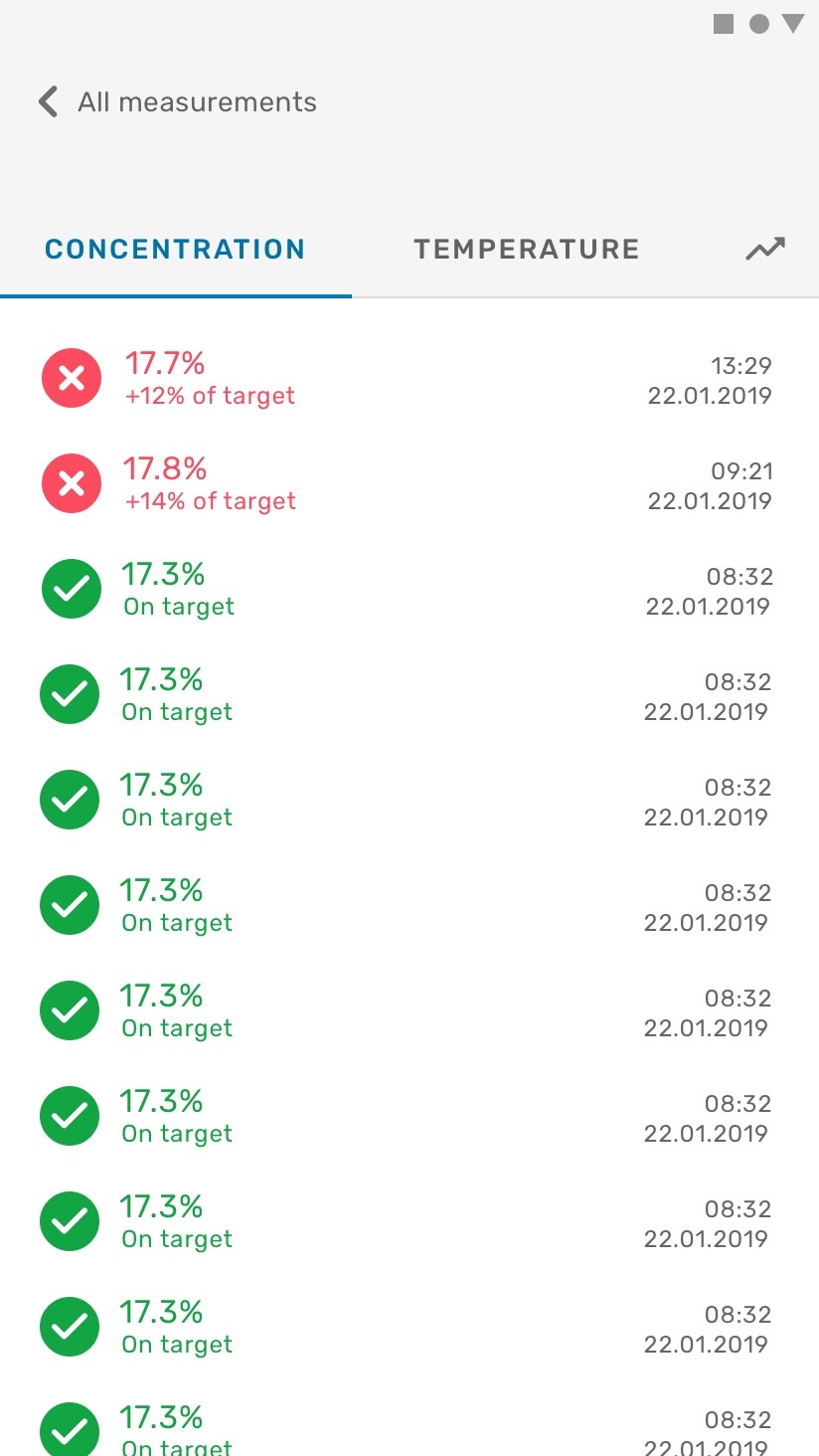

One level deeper

Tracking a coolant's health would be nothing without being able to have a detailed view into how it's performing. Therefore it was critical to design an easy way for specialists to keep close tabs on the sensor's live results.